measuring equipment to verify coating thickness|measuring wet paint mil thickness : Brand This method has widespread use for measuring thickness of paint and plastic coatings. The coating serves as a spacer between the probe and the conductive surface. As the distance between the probe and the conductive base metal increases, the eddy current field strength decreases because less of the probe's magnetic field can interact with the . Conclusion. Le nombre considérable de casinos en ligne proposant Google Pay a déjà attiré des milliers de nouveaux joueurs mobiles. Toutes les transactions sont gratuites et rapides. Les casinos avec Google Pay sont très faciles à utiliser et ils proposent tous des bonus et des promotions lucratives. Consultez notre liste des meilleurs .

{plog:ftitle_list}

FC Haka (Haka) on vuonna 1934 perustettu valkeakoskelainen jalkapalloseura, . Heti alkukaudesta lähtien KTP hallitsi lähes suvereenisti Ykköstä ja vaikutti kauden puolivälissä täysin varmalta nousijalta ja seuraan viime kauden päätteeksi siirtynyt Jussi Aalto varmalta maalikuninkaalta. Haka puolestaan pelasi vaihtelevin tuloksin ja .

The ultrasonic pulse-echo technique of ultrasonic paint thickness gages (e.g. PosiTector 200) is used to measure the thickness of coatings on nonmetal substrates (plastic, wood, etc.) without damaging the .Destructive paint inspection gages measure the thickness of single or multiple coating layers by cutting a groove into the coating system using a precise angle and measuring the cut using a 50x microscope and reticle.

The PosiTector 200 C Ultrasonic Coating Thickness Gage (Standard or Advanced) is ideal for measuring most paint and coatings on concrete applications.With a paint thickness measurement range of 50 to 3,800 µm (2 .A reversible anvil lets you adapt the gauge to the shape of the object you are measuring. Use the round face on the anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat face to measure sheet metal, paper, and other flat stock.This method has widespread use for measuring thickness of paint and plastic coatings. The coating serves as a spacer between the probe and the conductive surface. As the distance between the probe and the conductive base metal increases, the eddy current field strength decreases because less of the probe's magnetic field can interact with the . Proper coating thickness is crucial in both functional and decorative plating. . Topics covered include analytical equipment, measurement methods and specific applications. Dr. . robots at Mercury Marine's global headquarters in Fond du Lac, WI. Date: Tuesday, November 12, 2024 Time: 4:30 PM Check-in | 5:00 PM Dinner & Presentation Location .

Calibration on the Coating Calibration and verification of accuracy is described in ASTM D 7091 Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Nonferrous Metals.

Coating thickness measurement is necessary to assess whether the coating’s protection level is adequate. Actual recorded film thickness of the PCB is compared to job-specific thickness requirements, to ensure standards are met. These specifications offer guidance on measuring the thickness of conformal coatings, whether the film is dry or wet .

Elcometer's latest innovation, the new Elcometer 456 sets new standards in coating thickness measurements. Available in a range of models for measuring dry film thickness on ferrous & non-ferrous metal substrates, the new Elcometer 456 is even more powerful, rugged and easier to use than ever before. Learn more about Coating Thickness Gauges.Anodizing Coating Thickness Measurement Solutions The PosiTector 6000 "N" series of eddy current gages are ideal for non-destructive measurement of nonconductive coatings on non-ferrous substrates. The PosiTector 6000 NAS probe is specifically designed for high resolution measurement of anodizing on aluminum. Though capable of measuring up to 625 μm (25 .So, it may be necessary to measure or verify individual layer thickness after the fact using destructive means. Destructive testing of thickness is also valuable for coating failure investigations. This issue of KTA’s Certified Coating Inspector Forum focuses on destructive coating thickness measurement. Standards and Instrumentation

An example of one is shown in Figure 2. Every powder coating operation should know what equipment is available and how to use it. . quality, or customer requirements for process control, companies need to verify coating quality to avoid wasting money reworking product. . Non-contact coating thickness measurement instruments have the .The coating thickness measurement range of the PosiTector 6000 paint meter is dependent on which interchangeable probe is attached. PosiTector 6000 probes are available for measuring a wide variety of coating thickness applications. . Powder coating inspectors often need a means to verify the thickness of powder coating on parts as early as .

Overview of magnetic and eddy current measurement principles. When it comes to coating thickness measurement, two commonly used principles are magnetic induction and eddy current.Let’s take a closer look at each of these principles: 1️⃣ Magnetic Induction: Magnetic induction is a widely employed method for measuring coating thickness.It operates based .

Measuring Hard Chrome Plating Thickness. Q. I'm looking for a non-destructive method to accurately measure hard chrome plating on a 14" diameter x 50" long forged steel roll. Chrome plating thickness is .0001" - .0004". Our chrome plater tells us that magnetic induction methods are not reliable or repeatable. Thanks. Michael Hoke 1998 How can we measure and verify that an ENP coating meets specification? Key deposit parameters are thickness, phosphorous content (%P) and hardness. Thickness Measurement. Primarily a function of immersion time, although the plating rate can vary with changes in plating solution chemistry, temperature, and pH, so regular checks and .

Topics covered include analytical equipment, measurement methods and specific applications. . robots at Mercury Marine's global headquarters in Fond du Lac, WI. Date: Tuesday, November 12, 2024 Time: . The assumption is that the coating applied to the structure has the same thickness as was applied to the coupon. However, the applied coating thickness may vary enough to create problems. One test method that can be used to measure TSA coatings, as applied to nitic stainless steel, is phase-sensitive eddy current (PSEC).

AS3715 is an Australian standard that focuses on the measurement of dry film thickness in the corrosion protection industry. As per this standard, it is imperative to ensure an average coating thickness, on any significant surface area, shall be a minimum of 60µm. Similarly, AS 3894.3 is an Australian standard that specifically addresses the .Non-contact coating thickness instruments have the advantage of being non-destructive. This means that after measurement, the measured components can be re-introduced into the process without being damaged. Other Methods in Powder Coating Quality Control. Micrometers are sometimes used to check coating thickness.

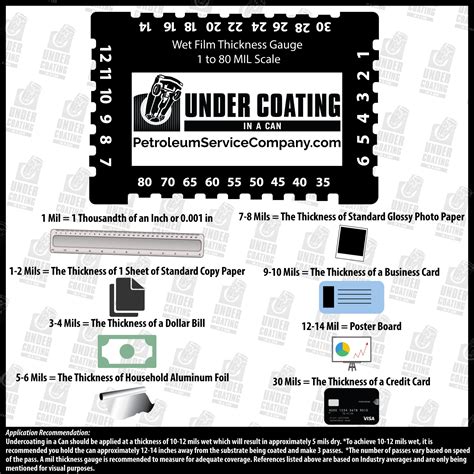

measuring wet paint mil thickness

pable of measuring the weight or the thickness of sig-nificantly thin coating layers of few atomic layers up to the so-called saturation thickness (typically in the range of 6 to 60 µm), depending on the density, the average atomic number of the coating layer, and the energy of the emitted lines used. In the past, XRF has been used to measure ..mgz-element.jvhf3a7 .image-content{width:100%;text-align:center;}.mgz-element.jvhf3a7 .image-title{font-size:16px;}Fast Coating Thickness MeasurementsThe Elcometer 456 Coating Thickness Gauge enhances efficiency by providing 70+ dry film thickness readings per minute (140+ per minute when using a scan probe). The Elcometer 456 mil gage has multiple .The specification ASTM E376 contains information for measuring coating thickness with magnetic and electromagnetic gauges as accurately as possible by explaining how and where to take measurements as well as guidelines for reducing errors. A few key requirements include: Readings should not be taken near an edge, hole, or inside; Measurements on large products . Step 4: Measurement of Coating Thickness. Step 5: Correction for Base Metal Reading (if acquired). Each of these five steps will be described in this article. Some History. SSPC-PA 2, was originally published as a temporary standard over 40 years ago in 1973 (73T) as “Measurement of Dry Coating Thickness with Magnetic Gages.”

Fig.1: A PosiTector 6000 NS1 measures on an acrylic coated printed circuit board with a solid copper ground plane. Solution #2 : For PCBs without copper ground planes. Our ultrasonic PosiTector 200 B gage measures conformal coating thickness on some printed circuit boards without a copper ground plane. Ultrasonic measurement has limited application on PCBs .Example A: Imagine you take a measurement on a steel coil coated with zinc galvanize using a PosiTector 6000 F gage and obtain a single-side thickness reading of “0.35 mils.”This can be easily converted to oz/ft² using the following method: Multiply the gage reading of 0.35 mils by 2 to account for both sides of the panel (0.70 mils)What is coating thickness measurement? . a calibration certificate is issued in which the procedure of the check, the measurement results and the deviations are documented. These certificates can be used to prove the accuracy of the coating thickness gauge at the time of testing. . Among the decisive criteria for the selection of equipment .Measuring physical parameters such as coating thickness, surface profile, and dew point is a common task for inspectors and applicators. . These SRMs are highly accurate artifacts that are used as calibration standards for the most precise measurement equipment. Because it's not affordable, efficient or even possible for everybody to .

characterize 2D/3D surfaces, for measuring wet and dry conformal coating thickness. In this work, conformal coating wet and dry thicknesses were measured using CCM and traditional methods. FR4 boards with varied color solder masks and components were created for realistic use cases. For wet coating thickness, CCM and

instron tensile compression tester model 4481

instron tensile compression tester model 4481 diagrams

WEBWatch Now. Pluto TV. Movies and Shows in Brazil. Stream Naruto Shippuden free and on-demand with Pluto TV.

measuring equipment to verify coating thickness|measuring wet paint mil thickness